Heavy Duty Beam Section ATL 100

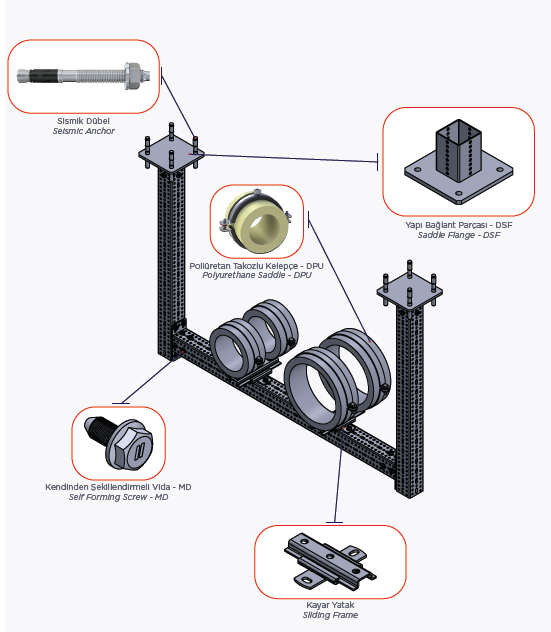

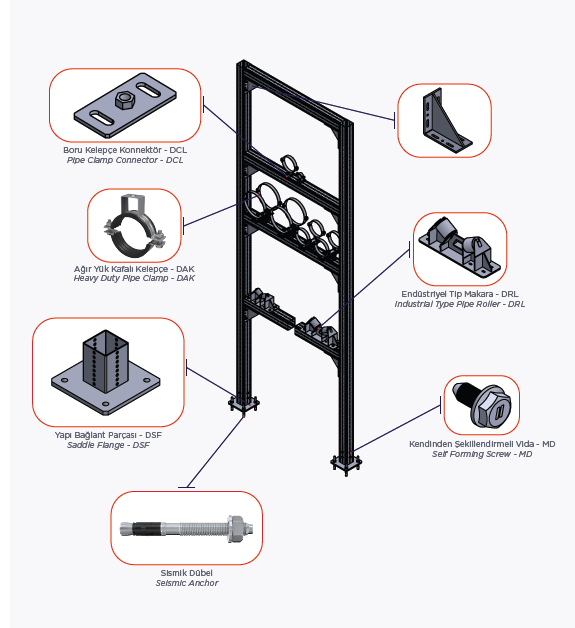

Eurocode3 and CE certified Atlas Heavy Duty Profiles are assembled on-site without welding thanks to self-forming screws and functional fittings.

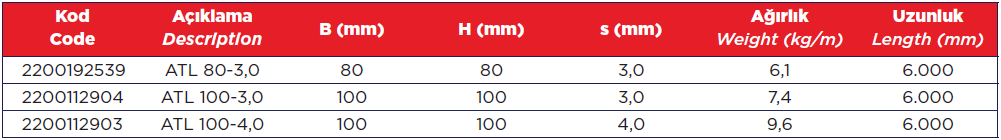

ATL 80.3

ATL 100.3

ATL 100.4

Atlas Heavy Duty Beam Sections provide vibration-resistant connection by leaving zero gap between the fitting and the hole thanks to its special self-forming screws.

Atlas Heavy Duty Beam Sections are assembled on site without the need for welding thanks to their self-forming screws and functional fittings. Thus, both manufacturing and application time is shortened.

Atlas can be integrated with other Darhan system solutions thanks to its hole structure.

The assembled fittings can be disassembled and reused thanks to the screws.

Material : Steel S235JR (material no.1.0038) acc. to DIN EN 10025-2

Galvanisation : Hot-dip galvanised, min. 75 μm, acc. to DIN EN ISO 1461

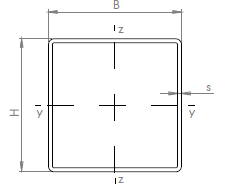

Cross-sectional dimension: 80x80x3

Advantages:

- Vibration-resistant connection with self-forming MD Bolt

Atlas Heavy Duty Beam Sections provide vibration-resistant connection by leaving zero gap between the fitting and the hole thanks to its special self-forming screws.

- Strong Structure

Atlas Heavy Duty Beam Sections made of first class steel material are lighter than other heavy load box profiles despite their strong structure.

- Fast assembly

Atlas Heavy Duty Beam Sections are assembled on site without welding thanks to self-forming screws and functional fittings. Thus, both manufacturing and application time is shortened.

- Disassemblable feature

The assembled fittings can be disassembled and reused thanks to the screws.

- Compatible with other Darhan product groups

Due to its Atlas hole structure, it can be integrated with other Darhan system solutions.

Application:

Energy : Power plants, Oil & Gas (offshore and onshore), Mining

Infrastructure : Airports, train, metro hospitals, water treatment, water supply

Industry : Chemical/Pharmaceutical, Automotive, Machinery